Attributes of the composite product depends on:

1、properties of used initial materials;

2、it's construction;

3、production technology.

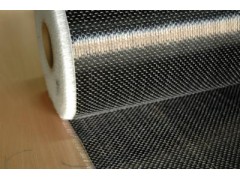

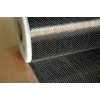

Effect of initial raw materials on composite products is obvious. Reinforced fibres determine resistance attributes. Most widely used in industrial practice are glass fibres, which owe its' popularity to perfect resistance and usable attributes with relatively low price. For more stiff constructions there are used carbon fibres, which are characterized by the higher modulus of elasticity. There are often used so-called hybrid strengthenings in a form of mats or fabrics, in which cheaper glass fibres are jointed with carbon fibres. Such a strengthenings are used for example in manufacturing of record-seeking boats.

Fibres made of aromatic polyamide (kevlar®, twaron®) and high-resistant polyethylene fibres obtained in a special technology process (dyneema®, spectra®)can be numbered among second generation of reinforced fibres. These fibres are much more lighter than glass fibres, and owing to exceptional high mechanical strength they have found an application in production of ballistic covers (bulletproof vests and helmets).

Among third generation of strengthenings there can be numbered fibres, which are monocrystals of the metals, metal oxides and metal nitrides. Owing to monocrystalline structure, these fibres' strength and modulus of elasticity corresponds with attitudes of interatomic bondings and repeatedly exceeds value of this characteristics for traditional materials. In technical literature they are called the whiskers. They have diameter about 1 micrometer and proportion of length to diameter is at least 10:1 (in comparison - proportion of diameter of typical glass reinforced fibres is about 11 micrometers). Considering the price, usage of the whiskers is limited to articles with the highest technical requirements, for example in technical of cosmic examination.

Binders (matrix) effect essentially on many composites usage attributes, such as resistance to external agents' activity (chemical resistance, thermal resistance, weather resistance, scratch resistance and the like), its manner in case of fire (flammability, emission of harmful substances while burning) and many others. Kind of a binder determines also possible ways of production of composite products. Talking of polymer binders, there is used very often conception of resin composition, which includes resins with strengthening set used for its hardening and other additions (fillers, pigments, additions which reduces the flammability and other enriching additions), which affect essentially on final composite attributes. Hereafter, there are main characteristics of generally used polymer binders discussed in a big short.

Polyester resins. Polyester resins, owing to theirs perfect processing attributes, possibility of using practically in all technologies of manufacturing of the composites, low price and quite good using attributes, are the most widely used thermosetting resins for production of composites. Therefore there is gigantic production and huge variety of many kinds of the polyester resins with attributes concordant with customers' needs. Polyester resins' fault is theirs relatively big shrinkage while hardening.

Epoxide resins. These resins are more expensive and more difficult in processing than polyester resins, but they distinguish by a very small shrinkage. They are used for example in manufacturing of production instrumentation of composites, wher precision of production is very essential (models, patterns, moulds, welding and assembling instruments, press-tools and the like)

Vinyl-ester resins. These resins, owing to theirs chemical structure, joint some of characteristics of polyester resins and some of characteristics of epoxide resins. They have similar processing characteristics and they are cured in a similar way like polyester resins, but they also have some of profitable epoxide resins attributes. They distinguish themselves in particular by good chemical and thermal resistance and dimensional stability. They are used for example in building chemical resistant pipelines and chemical equipment and also – as just as epoxide resins – in precise production instrumentation.

Phenolic resins. In distinction to the resins discussed above, which are cured by polymerization (without emitting by-products), phenolic resins are cured by the process of polycondensation (with water emitting) and they are cured normally using much higher temperature and higher pressure. Phenolic resins in a form of moulding composition, first with cellulose fibres, later with glass fibres, they are historically one of the oldest products which have been manufactured of plastics. Nowadays phenolic resins are processed – as just as polymerizing resins – also without pressure, using restrainedly raised temperature. It allows to produce large-size articles in relatively short series (there are no expensive moulds needed). In these articles, for example elements for building and equipping the railcars, there are used perfect attributes of phenolic composites. They are resistant to high temperature, they are practically non-flammable and they emit very little amount of harmful substances in case of fire. There is no need to point especially how important it is for metro railcars which run in tunnels. These articles which are made of phenolic composites manufactured this way, they require painting considering their not to good aesthetic attributes, yellowing as the effect of the light and porosity which requires removal.

The above – described in short – review of raw materials appears how many possibilities of regulating attributes of composite product by means of using different binders and reinforced fibres there are. There are many possibilities of moulding the desirable functional attributes in efficient compile of construction and selection of efficient manufacturing methods.

In “Methods of manufacturing of polymer composite products” we are trying to show how many various technologies of forming composite products there are and how to achieve requisite profitable scale of production through selection of efficient manufacturing method and how strict is correlation between products' attributes and theirs construction and manufacturing techniques.