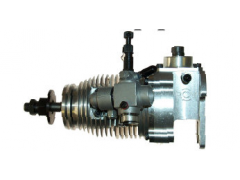

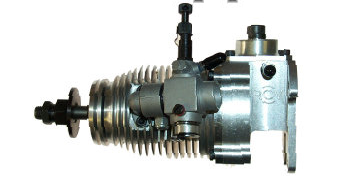

The RCV - rotary cylinder valve four stroke engine represents a major advance in model engine design. Although its moving components (piston, crank, cylinder and rotary valve) are totally conventional, they are arranged in a radically novel configuration to provide the aero modeller with several key benefits, whilst havin similar handling characteristics to other 4-stroke model engines:-

The RCV90-SP was designed with the scale modeller in mind. This quality CNC machined engine has a similar power output to conventional poppet valve 4-stroke engines and can be used in scale or general sport models that would normally use a 4-stroke .90 or a 2-stroke .60. However the RCV SP series offers much more. The compact streamlined shape means that cowled installations are that much simpler to arrange, perfect for warbirds, and the 2:1 output gearing allows for larger scale like propellers. The engine still uses RCV's unique rotary valve system - which has only one extra moving component to a 2-stroke and so is easy to maintain. One more benefit to RCV SP engines is the behind the prop starting facility (now included with the engine), which allows the modeller to stay behind the prop at all times So if you are looking for a reliable, streamline 4-stroke engine, that is capable of pulling scale size 2, 3 and 4-bladed propellers, our RCV90-SP engine is a perfect option.

The RCV 4-cycle engine has only one more moving component than a 2-cycle engine -the rotating cylinder itself. The cylinder is suspended between two bearings which allow it to rotate freely around the piston; the piston, and crank are entirely conventional. A gear formed around the base of the cylinder meshes with a gear on the crank. As the piston reciprocates and the crank turns, the cylinder rotates around the piston. At the top end of the rotating cylinder there is a single port leading to the combustion chamber. This is surrounded by a fixed timing ring with three radially arranged ports; inlet, ignition and exhaust. This simple valve arrangement serves the combustion chamber as the engine cycles through the conventional 4-cycles: induction, compression, power and exhaust. Ignition is achieved through a standard 4-cycle glow plug exposed once only during each complete cycle.