Kennametal Stellite's specialized coating services activities involve the application of wear and corrosion resistant alloys to components manufactured from soft, wear-susceptible base metals. These coatings significantly increase resistance to the principal forms of wear, encountered in extreme industrial environments, namely high temperature, corrosion and abrasion.

Kennametal Stellite uses various thermal spraying techniques to apply wear resistant coatings to components, including High Velocity Oxygen Fuel ("HVOF") spraying, plasma spraying, and flame spraying. Thermal sprayed coatings are characterized by a mechanical bonding with the metal substrate and are particularly useful for temperature-sensitive base materials.

Kennametal Stellite provides its customers with a range of machining services as a core element of its coating services offering, as well as additional value-added services including polishing, final assembly and testing. As well as providing you with a full spectrum of coating services from its key locations in Belleville, Goshen, Koblenz, Shanghai and Swindon, Kennametal Stellite also has an established international location in India. These provide dedicated, rapid local coating services to key customers, typically for coated components that wear regularly under extreme conditions and require frequent re-coating. Such applications are commonly found in the oil & gas, power generation and aerospace industries.

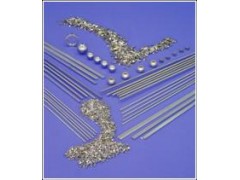

Coating