Since man first began to cast, he has had to contend with two troublesome factors: the interaction of atmosphere with the molten metal and the temperature loss of the molten metal bath. The consequences of these factors � dross, impurities and internal defects � seriously impact the quality and integrity of the final casting.

These physical phenomena can only be completely eliminated by melting and pouring the metal in a complete vacuum � a process deemed too expensive for conventional cast products and usually reserved for special alloys and critical components that can carry the cost burdens.

However, the following practices can significantly reduce molten metal oxidation and temperature loss:

Minimized time molten metal is held at elevated temperatures

Minimized exposure of the molten metal stream to the atmosphere

Reduced or eliminated metal contact with surfaces of lower temperature

Surprisingly, these are practiced by very few foundries. Generally, foundries bring large volumes of molten metal to superheated temperatures and then hold them at these temperatures as appropriate charge quantities are tapped and transferred to smaller ladles that are used to fill preheated molds. Typically, gas flames preheat these ladles while the metal is being melted. As soon as they are removed from the heat source, there is a resultant temperature loss. There is also an increased probability of metal contamination because of inherent breakdown of ladle material.

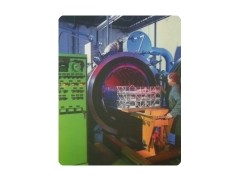

In contrast, Vestshell has pioneered an efficient method by which the molten metal can be poured directly from the melting vessel without transfer to a pouring ladle. By melting and pouring from the same vessel, we ensure that there is no temperature loss during a transfer, since no transfer takes place. Additionally, as the metal is contained in only one vessel, there is half the opportunity for breakdown in the ceramic liner material. Our deslagging process, done just prior to pouring, removes the minimal amount which may have occurred.

Secondly, since we size each melt batch for the molds that are being poured, metal volume at superheat is held to an absolute minimum. Within a very short time span, the charge is melted, brought to (and held at) the proper temperature and then the complete charge is poured into the preheated mold. In these smaller batches, more accurate temperature measurement is also possible. In larger volumes of molten metal, stratified temperature layers make it difficult to maintain the narrow temperature ranges often demanded by today抯 complex and intricate castings.

Thanks to our direct pouring techniques, Vestshell customers avoid the tremendous hidden costs of unseen internal defects. These defects, which find their source in slag oxides or non-metallic inclusions, can have disastrous results: machine shops damage expensive tools; added-value products are scrapped or reworked; end products fail in service; products are recalled; and companies are exposed to liability issues . . . to name only a few.

We encourage you to compare foundry production methods for yourself. For forty years, Vestshell customers have reaped the advantages of direct pouring � and have confirmed our commitment to delivering the better total value, not just the lower unit cost.

Direct Pouring