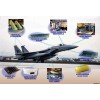

IAI-CAG's Sheet metal Center focuses on "Ready for Assembly" Stretch Formed Parts.

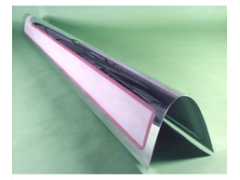

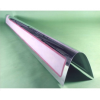

The Stretch Forming Center includes two Stretch forming facilities, thus increasing the center's ability to provide high-quality parts at the lowest price. The Sheet metal Center produces all parts with double curvature geometry, including fuselage skins, wing leading edge segments, horizontal and vertical stabilizers leading edge panels.

The Stretch Forming Center is supported by in-house state-of-the-art facilities:

Surface Mechanical or Chemical Milling

Heat Treatment

Surface Treatment

NC Trimming - metallic & Composite

Painting

Sheet metal Center

Recently, IAI-CAG introduced into service the MTorres Surface Removal Milling Machine, a revolutionary technology for mechanically performing the aircraft skins thickness reduction process, traditionally executed using chemical milling. The mechanical milling advantages include:

Milling, routing, drilling, inspection & quality control are performed in one location without moving the part.

Skin thickness control (in the pocket) is maintained during the milling process

Higher and better accuracy

Reduction of cycle time & labor cost

Elimination of chemical line's operations cost and environmental issues

All scraped aluminum can be recycled