Search

|

Home » Welcome

History:

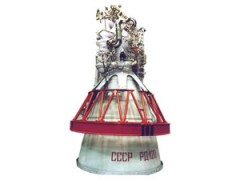

History:History of NPO ENERGOMASH is closely linked with of V.P.Glushko's creative activity – the founder of domestic liquid propulsion engineering. V. P. Glushko was permanent leader of the company up to 1974 when he was at the head of NPO «Energia» which structure included Design Bureau Energomash and Experimental Plant ENERGOMASH till 1990. May 15, 1929 – formation of group under leadership of V.P.Glushko to develop electric and liquid rocket engines within Gasdynamic laboratory (GDL) in Leningrad. September 1933 – continuation of works under the Reactive Scientific- Research Institute (RNII) in Moscow, created on the basis of GDL and Moscow group of studying reaction propulsion (MosGIRD). 1939–1940 years – work at OKB (Design Bureau) of 4-th Special Department of People's Commissariat of Internal Affairs at Tushino' Aviation Motor - Building Factory №82 1940–1944 years – work at OKB of 4-th Special department of People's Commissariat of Internal Affairs at the Kazan Plant №16. 1944 year – organization of Experimental Design Bureau of special purpose engines (OKB-SD) under leadership of V.P.Glushko in Kazan. 1946 year – moving of OKB-SD to Khimky and organization of Experimental-Design Bureau №456 (ОКB-456) on development of powerful LPRE in Khimky, Moscow area, later modernly named - NPO ENERGOMASH named after academician V.P.Glushko. V. P. Glushko, graduator from Leningrad University was invited in 1929 to Gas Dynamic Laboratory (GDL) to implement the ideas, identified in the special part of his diploma work named “metal as explosive”. As a result of the activities of the team under leadership of V.P. Glushko, the first in the world electro-thermal rocket engine was developed and the patent for this rocket engine design was received. Since 1930 his attention has been completely devoted to development of the LPRE. In 1930–1931 years in the GDL under Glushko’s leadership the first in the USSR liquid rocket engines - ORM (experimental rocket motor), ОRM-1 and ОRM-2 - have been developed and produced. In 1931 47 bench tests of experimental LPREs such as ORM and ORM-1 were conducted. There were works not only on development of specific designs, but also ways for advance designs were investigated. For the first time cardan mount of engine with pump units and a number of other ideas have been offered. For the first time nitric acid and a number of other substances are offered and are investigated in the further as rocket propellant by Glushko. Not only works on development of certain LPREs were conducted, but also the ways for advance designs were investigated. For the first time cardan mount of engine with pump units and a number of other ideas were offered. For the first time nitric acid and a number of other substances were offered and investigated in the capacity as rocket propellant by Glushko. In 1932 the designs of experimental LPREs (from ORM-4 up to ORM-22) for research of a type of ignition, a method of start-up and systems of mixture were developed for tests using various components of propellant. In 1933 a number of engines such as ORM-23 up to ORM-52 with pyrotechnic and chemical ignition were developed and tested and the design of TPU with centrifugal pumps was developed as well. Within the period from 1934 to 1938 the department under the leadership of V.P.Glushko developed and tested the engines starting with ORM-53 up to ORM-102. ORM-65 engine for rocket glider RP-318-1 and cruise missile 212 was the best domestic engine of that time. Within the Second World War the designs of airplane LPRE - accelerators for airforce were created: RD-1, RD-1KhZ with thrust of 300 kgf, RD-2 with thrust of 600 kgf, experimental three - chambers engine RD-3 with thrust of 900 kgf. These engines have passed about 400 start-ups on airplanes PE-2R, LA-7R and 120R, Як-3, SU-6 and SU-7 of V.M.Petljakov, A.S.Lavochkin, A.S.Yakovlev, P.S.Sukhoy designs. RD-1 and RD-1KhZ engines have passed the state tests, the reports on those have been approved by I.V.Stalin. Since 1944 RD-1 engine production and since 1945 RD-1KhZ engine production has been initiated on a serial level. In June 1945 the group of workers of OKB-SD was sent to Germany to study German trophy techniques. Acquaintance with German experience of development of А-4 (FAU-2) rocket and understanding the necessity to have similar armory in the Red Army favored the release of Government Decree on arrangement Special Committee for reactive engineering in a short period of time. Putting into effect this decision a number of companies including ОКB-456 for development of powerful LPREs, have been organized. In the end of 1946 ОКB-456 was located in Khimky at the place of former aviation factory №84 wher V. P. Chkalov was a chief-pilot. In the beginning of the War this factory was evacuated to Tashkent wher it nowadays exists. At the territory of the industrial facilities left during the war period Repair Aviation Company (plant №456) for military aviation was organized. For a short period of time the buildings for engine manufacture have been constructed, stands for fire tests of engines and their main units have been built. The decision to reproduce the engine of the German rocket and then to move further was accepted. RD-100, developed for R-1 rocket, is the reproduced copy of the German engine made of domestic materials and in accordance with domestic technology. A little more powerful in thrust RD-101 and RD-103 engines for R-2 rockets and R-5М rockets correspondingly were developed by modernization of RD-100. With some design improvements for cooling, thermal protection and strengthening it was possible to increase pressure and temperature in combustion chamber with an increase of concentration of fuel at the same time. Many systems and elements of LPRE have been changed. The decision to terminate the development activities on the basis of German engines design and speeding up of the works conducted on experimental chambers KS-50 and AD-140 with the purpose to determine an opportunity of increasing pressure and temperatures of gases in the combustion chamber was made. The new chamber appeared to be efficient at temperatures up to 4400 K of high pressure gas. The opportunity to use engines high performance propellants was opened. Such design and technology of its manufacturing began to be widely used for all subsequent NPO ENERGOMASH developments and within other design bureaus of our country. In 1957 all world learned about the successful flights of the first intercontinental missile R-7 in the USSR which would soon put into orbits the first satellites of the Earth. At the first and second stages of "Vostok" LV by means of which the first satellites launches were conducted and the first manned flight into space was carried out, RD-107 and RD-108 four-chamber oxygen-kerosene engines with steering chambers for control of rockets flight direction were installed. Multi-chambers allowed to significantly reduce the engine length that led to the rocket length reduction. Besides, this decision allowed to simplify technological development of these combustion chambers as well as to decrease overall dimensions of industrial & processing equipment, necessary for their manufacture. The principle of multi-chambers continues to be widely used in various new LPREs of NPO ENERGOMASH. D.Kennedy, the US President, in his special message to the Congress, dated May, 25th,61 “about the major goals of the country” wrote:“We became the witnesses of the fact that the first achievements in the space were done by the Soviet unio owing to their powerful rocket engines they have. This assured their leading role…” RD-107 and RD-108 engines were developed within 1954-1957 years. They and their modified options operate within the space launch-vehicles which have put into orbits artificial satellites of the Earth and the Moon, space vehicles for research of solar system. Even today they reliably provide for completion the Russian manned flights space program. In the end of 90th years - the beginning of the new century the activities on modernization of the engines for "Souyz" LV with a new mixing head (RD-107А and RD-108А) were conducted. Since May 2001 these engines have been used for launches of "Progress" cargo vehicles and since October 2002 – for manned "Soyuz" LVs. Nowadays the works on introduction of the system of chemical ignition instead of pyrotechnic ignition are conducted. 12 fire tests of 2 engines with chemical ignition has been conducted (RD-107A and RD-108A), full readiness for performing certification and flight tests of new modification of the engines. In parallel with these works NPO ENERGOMASH conducted development of the engines operating with long term storable propellant for use in missiles. In 1952-1957 RD-214 LPRE operating with nitric acid was developed. It was the introduction of LPREs which operated with high-boiling propellants. In 1958-61 RD-216, RD-218 and RD-219 engines were developed for the first and second stages of missile R-16 and one of the variants of "Cosmos" LV, operated on nitric acid and nonsymmetrical demithyl hydrazine (UDMH). In 1961-65 six-chambers engine RD-251, consisting (as well as RD-218) of three two-chambers blocks was developed. This engine operated with nitric tetroxide and UDMH. RD-252 for the second stage had one block. As a result the task to design powerful many - chambers engines operating with high-boiling components during a short period of time was solved by application of block schemes of engines with max unification of their elements. The engines of this line developed lately favored the missiles maximal readiness at start which could be wet for many years. The further increase of a specific impulse of engines demanded increase of working pressure in combustion chamber that was limited to losses on a drive of turbopump unit. Final solution of the problem was found in the new scheme of the LPRE: generator gas worked out in the turbine then after-burned in the main combustion chamber at mixture with a missing component of propellant. Pleasure rise by several hundred atmospheres allowed to build engines of great thrust with significantly reduced, in comparison with the former ones, dimensions. In 1961-1965 years the development of RD-253 engine for "Proton" LV became great practical achievement. It is the most powerful single-chamber LPRE, operating with high-boiling propellants. For the first time in the world so powerful engine was built according to the scheme with afterburning of oxidizer-rich gas that considerably increased the engine efficiency. Pressure in the combustion chamber was 150 atm. Next years the engine systems operating with high-boiling propellants with closed loop for missiles were developed. Engines RD-264 and RD-268 are installed on missiles R-36M (designation NATO-SS-18Satan, «Satana») and MR UR-100 (SS-17 Spanker, «Trotter»). RD-268 chamber pressure is 230 atm. Six RD-253 engines, reliably operating on the level of first stage of "Proton" LV, provided successful flights of space vehicles "Moon", "Venus", "Mars" and others, and also orbital space stations " Salut " and "Mir", elements of the ISS. In the end of 1990th modernization of this engine for use within "Proton-M" LV was conducted. New upgrade of the engine was designated as RD-275 (RD-275M). Thrust of the engine was increased by 7,7 % due to an increase in pressure in the combustion chamber that allowed to increase mass of a payload by 600 kg. First launch of "Proton" LV with RD-275 engines took place in October 1995. In 2001 Kamsky branch has initiated the design & development of RD-275M engine - forced by 5,2 % for thrust modification of production engine RD-275. Such increase in thrust of the engine allows increasing the mass of the payload put into a stationary orbit by 150 kg more. In 2002 – 2003 the design and technological documentation on RD-275M engine was issued, 4 fire tests of 3 development RD-275M engines with running time 735 sec were conducted. On May 4, 2005 the program of interdepartmental tests of 3 engines RD-275M was successfully completed. The first launch of "Proton-M" LV with engines RD-275M (14D14M) took place on July 7, 2007. In 1985 the development of the RD-120 single-chamber engine, intended for the second stage of "Zenit" LV and capable to put into the near Earth orbit a payload with weight up to 12 tons, was completed. Significant reserves of working capacity of the basic units and the engine as a whole allowed to develop on its basis the forced by 10 % of thrust modification with 93 tons thrust level and with safe margin by 5 % more and to obtain the life time of one engine operation such as 4260 sec, and a number of start-ups - up to 19, that allows to consider RD-120 engine and as a basis for reusability. These modernization works on the engine were conducted in 2001-2003. 4 engines passed 28 hot fire tests with running time 8135 sec. The first launch of "Zenit" LV with forced RD-120 engine under the «Sea Launch» Program was successfully conducted in June 2003. Modifications of this engine with shortened nozzle and cardan mount or with application of steering chambers for thrust vector control can be used at the first stages at modernization of the existing LVs and also at development of new LVs of small and middle classes. New step in development of LPREs for the new generation of LVs became the development of RD-170 engine and its modifications - RD-171 engines for the first stages of rocket - space complex “Energia - Buran” and "Zenit" LV accordingly. The most powerful in the world four - chambers RD-170 LPRE has the highest level of parameters and characteristics for engines of the given class and operates with ecologically clean propellants: liquid oxygen and kerosene. The engine is designed for reusability and has been certified for 10 times use. One of the engines has been fire tested up to 20 times. The engine is characterized by high reliability at all stages of operation, repairability and controlability and has a great life margin (no less than 5). The special system of health - monitoring after-flight conditions of the engine hardware has been developed. The special technology of inter-flight processing of the engine for preparation of the engine for a new flight or test has been mastered. Thrust vector control of the engine is carried out due to the design of the unique bellows unit of chamber gimballing, operating in a high-temperature gas flow zone. Power and operational characteristics of this engine have no domestic and foreign analogues. First launch of "Zenit" LV with RD-171 engine has been carried out in April, 1985. In 1987 and 1988 "Energia" LV/RD-170 engines launches took place. Since 1999 the operation of RD-171 engines continues within «Zenit 3SL» LV under «Sea Launch» Program. Modernization activities with RD-171 engine to be used in «Sea Launch» Program have been continued in the period of 2003-2004. Certification of RD-171M engine was completed on July 5, 2004 - 8 tests with duration of 1093,6 sec, and last test (out of the plan) - at mode of 105 % was conducted on the certification engine. The first production RD-171M engine was delivered to Ukraine on March 25, 2004. The first launch of “Zenit3SL” LV with RD-171M engine took place on February 15, 2006. RD-171M engines are used for «Zenit 3SL» LV (Federal Land Launch Program). Engines which are developed on the basis of four-chamber RD-170 engine have a plenty of attractive features and advantages as they are based on well proven designs of units and elements of the existing engine. In January, 1996 the project of two-chamber RD-180 engine became the winner of competition on development and delivery of rocket engines for modernized “Atlas III” LV of Lockheed Martin (USA). Development of RD-180 was conducted in cooperation with Pratt&Whitney (USA), the company NPO ENERGOMASH signed the Agreement with (in 1992) on joint marketing and licensing of engines of NPO ENERGOMASH in USA, and in 1997 they created RD AMROSS joint venture on marketing and sales of RD-180. Fire tests of RD-180 engine were initiated in November, 1996. The first launch of US “Atlas 3А” LV took place on May 24, 2000. The first launch of “Atlas 5” LV with RD-180 engine took place on August 21, 2002. In April, 2011 more than 70 production RD-180 engines were delivered to the USA. 51 launches of “Atlas III” and “Atlas V” LVs were conducted in June, 2011. In addition NPO ENERGOMASH is developing a single-chamber LPRE such as RD-191 for the family of new Russian "Angara" LV. The engine is based also on the design of RD-170 engine. RD-191 engine represents a single-chamber LPRE with vertically located TPU. Within 1999 the design documentation was issued, in 2000 year independent development of units of RD-191 engine was started, preparation for manufacture was completed. In May 2001 the first development engine RD-191 was assembled. The first fire test of RD-191 engine was conducted in July 2001. 3 fire stand tests of RD-191 engine on the level of the first stage (URM-1) were successfully conducted in 2009. Projects of three-propellant two-mode LPREs of the RD-700 family attract interest among experts of the space industry of the world. Such engines assure sequential operation: first at mode I - three components (oxygen - kerosene - hydrogen) with the maximal thrust, and then at mode II - two components (oxygen - hydrogen) with the maximal specific impulse. Reusable operation of the engine (up to 15 times) is stipulated. RD-701 two-chamber engine was designed for aerospace system MAKS, and RD-704 single-chamber engine can be a basis for realization of the perspective concept of a single-stage LV with a vertical launch and landing. Structure: NPO Energomash has a well developed infrastructure including all necessary elements of technological cycle of Liquid Propellant Rocket Engine (LPRE) production: Design Bureau with great intelligence and cadre capabilities. Design Bureau makes designer’s inspection over production of the engines and conducts engineering surveillance of the engines at production plants and at flight tests of launch vehicles. For these purposes the Design Bureau has a number of its branches (in Samara, in Perm, in St. Petersburg). The plant is equipped with modern multipurpose machines and purpose-designed equipment. Many trained workers and experts who assure development of technological processes as well as fabrication and assembly of rocket engines work for our company. Science – Test Complex, havin the unique test stand base (more than 70 test benches) for all types of tests of independent units and the LPRE intact, including two unique test benches for hot firing of the engine with thrust of up to 1000 tf. about 4100 people work for our company. Total area of the company – 92 hectares. [Detailed introduction] |