TEST SYSTEMS COMPOSITE PRODUCTION

Test systems for composite production are frequently to check a variety of variables. During (automated) production and re-work/finishing, products have to be tested and if necessary have to be rejected or repaired to meet predetermined measurements and tolerances. Weight (volume fraction), conductivity, dimensions, pressure and leakage are important variables for the production of high specification composite parts. Typical hydraulic fluids like Skydrol ® are commonly used in our (high) pressure test equipment for Aerospace.

Autonational Composites supplies the necessary equipment to achieve your technical specifications. Below you can find some examples of test equipment.

Please feel free to contact us directly to discuss your challenge! Project examples regarding our Division Integrated Solutions in Filament Winding can be found here.

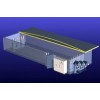

HYDRO-TESTERS FOR LARGE PIPE PRODUCTS

Autonational Composites has developed hydro testers for composite pipes with an adjustable length up to 12 m and a maximum diameter of 4000 mm. These test machines have a clamping force of 1.800 tons. Autonational applies a unique seal system, in which the pipe to be tested is clamped by hermetically sealing the rings under pressure and closing the tube without damage or air inclusion. The machines are automated, meaning that the tube is enclosed, filled, tested and emptied automatic.