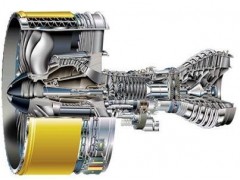

One of the main areas the company operates in is the production of sheet metal components of aerospace engines, mainly gas generators, gas exhausts, combustion chambers, turbine bodies, diffusers, discs, seals and compressor blades. The specialization in the range of sheet metal components includes:

-

cold-forming metal

-

forming metal with heating

-

resistance welding (spot, line welding)

-

welding (TIG, EB, plasma)

-

plasma spraying

-

diffusion coating

-

vacuum heat processing

-

vacuum soldering

-

laser processing

-

galvanized coating

-

unconventional processing (ECM, EDM)

-

NDT control (FPI, RTG digital control)

-

dimensional control (scanning, laser measurements).

All the production processes that have an effect on the condition of the material have the NADCAP accreditation (NADCAP is an international accreditation program).

One of the main areas the company operates in is the production of sheet metal components of aerospace engines, mainly gas generators, gas exhausts, combustion chambers, turbine bodies, diffusers, discs, seals and compressor blades. The specialization in the range of sheet metal components includes:

-

cold-forming metal

-

forming metal with heating

-

resistance welding (spot, line welding)

-

welding (TIG, EB, plasma)

-

plasma spraying

-

diffusion coating

-

vacuum heat processing

-

vacuum soldering

-

laser processing

-

galvanized coating

-

unconventional processing (ECM, EDM)

-

NDT control (FPI, RTG digital control)

-

dimensional control (scanning, laser measurements).

All the production processes that have an effect on the condition of the material have the NADCAP accreditation (NADCAP is an international accreditation program).