Molybdenum-niobium (MoNb) is used in touchpanels as particularly corrosion resistant wirings of the ITO sensor. You can rely on the quality of our MoNb sputtering targets. Because we are the only manufacturer of sputtering targets to perform every stage of the production process ourselves. From the purest metal powder through to the finished sputtering target. In our own bonding shops in Asia we fully prepare our MoNb targets for you. We deliver our MoNb planar targets and rotary targets in all common sizes.

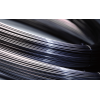

Rotary sputtering target

The most important facts

Density [%] ≥ 99.5%

Purity [%] > 99.97

Coefficient of thermal expansion [ppm/K] 5.38

Thermal conductivity [W/(m· K)] 103

Electrical conductivity [MS/m] 13.5 MS/m

Microstructure single-phase material, oxide-free

100% homogeneous. Chemical composition and film thickness.

Is a uniform gray area all that you can see in this SEM image of our MoNb? That's right! After all, homogeneity is the strength of our material.

Molybdenum-niobium

MoNb in electron microscope

In other MoNb targets, you will find molybdenum phases and niobium phases next to each other. This makes it a two-phase material. In contrast, our molybdenum-niobium is a single-phase material. It is made up of mixed crystal. We call this newly developed material MoNb Solid Solution. This means that the 100% homogeneous target material will subsequently become your 100% homogeneous thin film.

Because all the grains are of the same material, there is no relief formation during sputtering. The density of the film is uniform across the entire sputtering surface, as is the niobium content. The standard deviation for the niobium content is less than 1% by weight.

100% oxide-free.

Excellent powder quality We are experts in the manufacture of refractory metals using powder-metallurgy technologies. No matter whether they are round or flat, our MoNb targets are produced by carefully mixing ultra-pure metal powder. The powder is then pressed, uniformly densified in our sintering systems and then shaped to form your target.

In contrast to our competitors, we keep the oxygen content of our sputtering targets to an extremely low level. Of course, exactly how we do that is a well-kept secret. But you benefit from extremely high levels of material purity and by using our targets, you can largely avoid localized fusing on the substrate, known as the arcing effect.

Patent pending.

Patent sputtering target MoNb

We have already applied for a patent on our manufacturing process for oxide-free MoNb sputtering targets. So the choice is up to you when you purchase your sputtering targets. only in Japan are we unable to supply our MoNb due to patent protection considerations.

Are you already familiar with MoTa?

We are also able to offer our corrosion-resistant material molybdenum-tantalum for your touch panels. MoTa allows you to structure your films particularly quickly and easily.

You want the perfect coating? We create it.

In the PVD process, everything must fit together perfectly. only if all the process parameters are fully harmonized it is possible to create the coating that precisely meets your requirements. In our PVD application laboratory, we perform sputtering in near-real life conditions. Here, our team of developers creates coatings and conducts in-depth analyses based on your specifications. Thanks to this collaboration with you and a wide range of development institutes, we can minimize the time to market required for the development of new coating materials.

The best proof of our expertise is us! We coat many of our products such as semiconductor base plates and x-ray targets in-house using the PVD, CVD, APS and VPS coating processes.