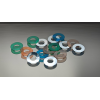

CNC Milling of a Mylar Washer for the Aerospace Industry

Due to our expertise in manufacturing washers from all types of materials, Shimco was contracted to produce a Mylar® washer for a customer in the aerospace industry. After reviewing the customer supplied specifications, we chose a CNC milling operation, rather than stamping or laser cutting, to produce the highest quality part possible. Utilizing our VMX Hurco CNC milling machines, we were able to quickly and cost-effectively mill and drill 30 units of this 7.201" x 1.302" x .062" washer according to the tight tolerances required by the specification. All parts were marked with the part number and underwent a rigorous quality control inspection before shipment to the customer in Quebec.

To learn more about this project or for complete details on our shim and washer fabrication services, please contact Shimco.

Product Description This polyimide shim is used within an assembly application.

Custom CNC Milling Capabilities Applied/Processes Primary:

Shearing

CNC Machinings

Mill Part as Per Drawing

Drilling

CNC Milling Gluing: Edgebond Glue 63 Layers to form a Thickness of .187"

Secondary:

Deburring

Abrasive Blasting

Passivation

Marking

Stamp w/ Part Number

Packaging Bag and Tag

Overall Part Dimensions Length: 7.201"

Width: 1.302"

Thickness: 0.062"

Tightest Tolerances ± 0.002"

Material Used Mylar

Testing/inspection performed In Process Inspection

Industry for Use Aerospace

Production Volume 96

Delivery Location St. Laurent Quebec

Standards Met Customer Supplied Specifications

Product Name Mylar Washer